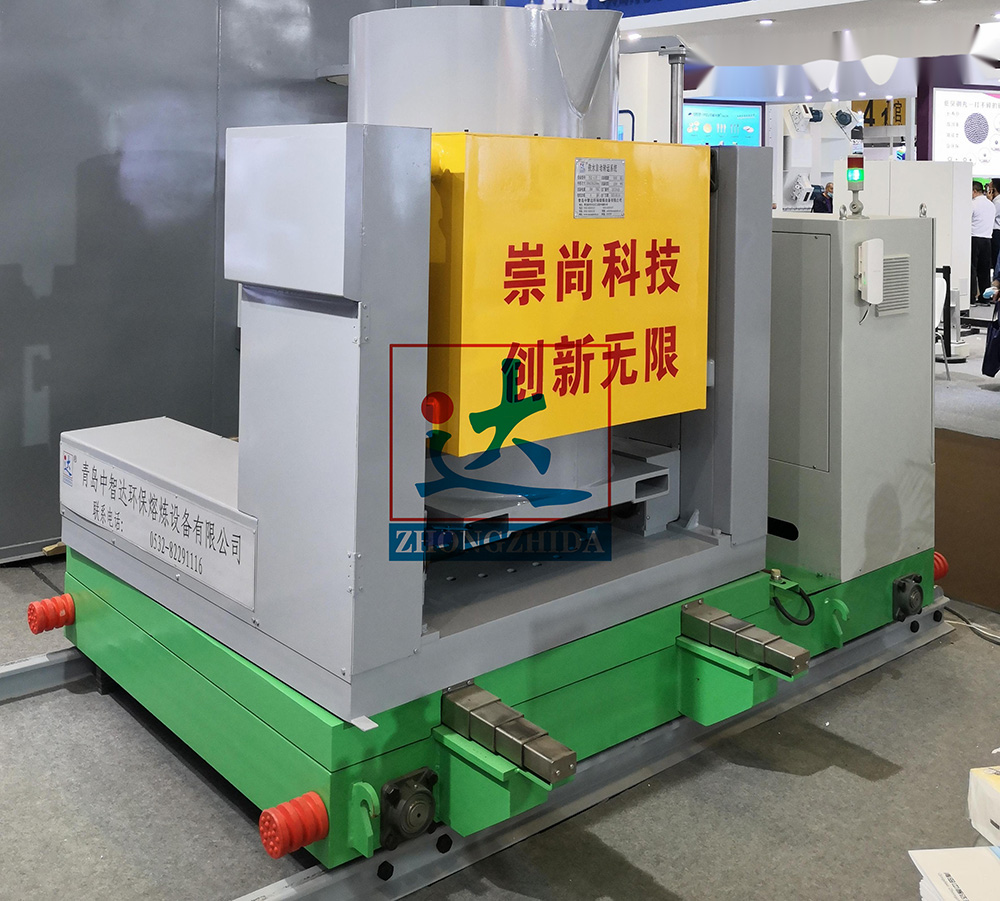

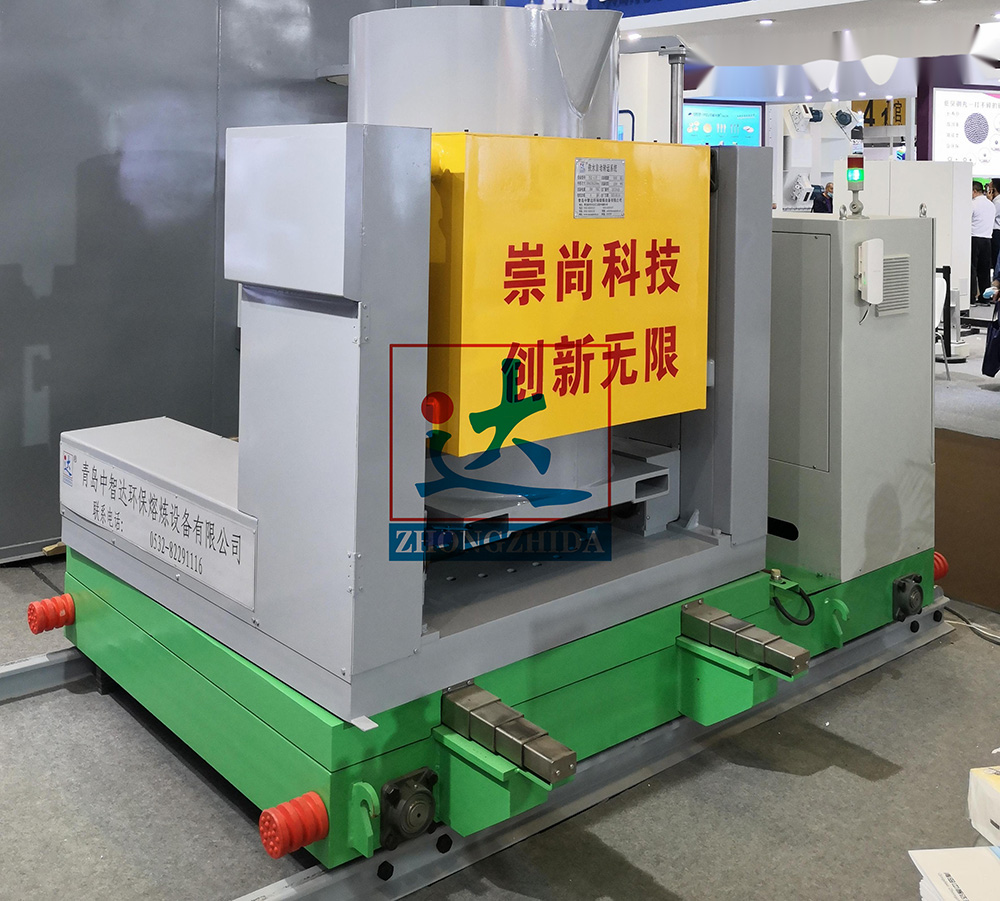

产品简介

由我公司自主研发设计的铁水智能转运系统,包含炉前转运车、倾转转运车、倾转提升转运车等多种形式。可实现铁水自熔炼电炉出铁水完成到注入浇注机的这一过程的完全自动化,包括自动接送铁水、自动球化、自动加孕育剂、自动倾倒铁水等一系列工艺流程。

工作流程

铁水转运车行驶到电炉下方的指定位置,等待接铁水。铁水转运车可实现前进、后退、平移、任意角度旋转等功能

接完铁水后,铁水转运车自动行驶到扒渣点

扒渣完成后,铁水转运车行驶到浇注机前,自动将转运车铁水包举升至适当的高度后,将铁水倾倒至浇注机专用包内

倾倒结束后,铁水转运车自动返回至电炉区指定位置,等待下一次出铁信号

技术特点

安全:相较于传统的行车运输或者人工叉车运输方式,无需人工操作,消除安全隐患

高效:根据生产需要,与电炉、喂丝球化站、浇注机等设备紧密配合,可实现24小时三班制连续生产,避免因长时间人工重复操作带来的低效问题

智能:使用Profinet无线通讯、激光测距检测、机械定位等方法,实现全程自动化无人作业。